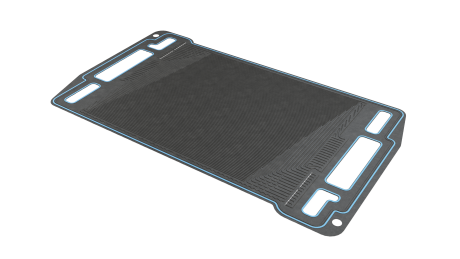

Bipolar plates

Hutchinson, with more than 70 years’ experience in stamping, surface treatment, overmolding and rubber-to-metal bonding, has developed cutting-edge expertise in bipolar plates. Designed for fuel cells, they play a crucial role in electrical conduction and fluid management. Manufactured from advanced materials, they offer high electrical conductivity and exceptional corrosion resistance.

Our qualified rubbers feature very low hydrogen permeability, while ensuring the proper functioning of fuel cell chemistry thanks to a low ion release rate. Our surface coatings meet customer requirements such as durability and conductivity. Our overmolding guarantees a perfect seal, while respecting functional and assembly requirements, enabling cell pitch optimization and optimal MEA operation. Last but not least, our know-how in half-plate assembly by soldering and our skills in air testing enable us to supply bipolar plates that are compliant and ready for assembly.

Features

- Rubber formula suitable for fuel cell environment

- Very low hydrogen permeability

- Overmolding solution for function integration on BPP bipolar plates

- Materials resistant to the acidity and humidity of hydrogen-rich environments

- Surface coating optimized for BPP corrosion resistance and electrical conductivity

Benefits

- Simplified assembly

- Large-scale industrial production

- Technical support during the BPP design phase

- Optimization of MEA operation

- Reduced cell pitch

- Extended fuel cell life