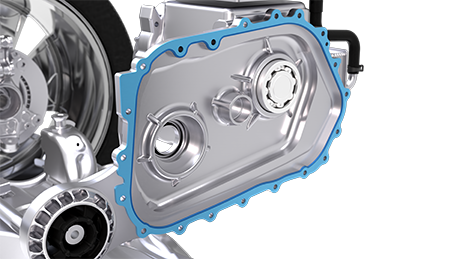

Bonded plate seal

Plate seals are bi-material rubber parts bonded on a rigid insert to facilitate assembly. They ensure sealing throughout the product’s life, thanks to the rigid backing that acts as a spacer for the fixing screws. Bonded gaskets ensure reliable closing, even in housings with stress-induced deformations or porosity. Our experts help you optimize the shape, thickness and number of screws for maximum performance.

Thanks to our expertise in materials, we define the best combination of elastomers (EPDM, ACM, AEM, HNBR, FKM, VMQ, FVMQ, etc.), bonded to high-performance rigid metal or thermoplastic substrates, to guarantee high-performance static sealing and enable our solutions to be used in extreme operating conditions, without compromising weight. Our solutions withstand high temperatures and intense pressure.

Our plate seals are approved for automotive, industrial, aerospace (AS9100, NADCAP) and military applications.

Features

- Wide range of reinforcement materials: steel, stainless steel, titanium, aluminum, magnesium

- Aerospace applications: withstands 3000 psi / 206 bar operating pressure and 9000 psi / 620 bar burst pressure

- Adhesion solutions adapted to substrates and operating conditions

Benefits

- Riliability

- Easy and safe assembly

- Easy to replace (maintenance)

Markets and expertise