Gaskets for fuel cells

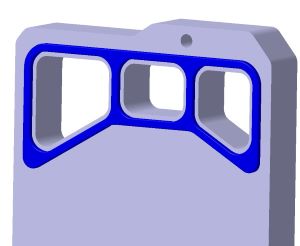

Hutchinson has developed EndPlate gaskets, essential components of electrolysis systems, designed for maximum sealing and operating safety. Drawing on our expertise in rubber gasket molding and our simulation and testing capabilities, we optimize the design to guarantee a flawless seal and ensure optimum performance.

A range of rubber compounds is specially formulated to control chemical contamination of batteries and ensure system integrity. The injection molding process is precise and reliable, guaranteeing proven adhesion to end plates, whether made of engineering polymers or steel.

Features

- Durability in acidic, oxygenated and hydrogenated environments

- PFAS-free rubber for fuel cells

- Precise, reliable injection molding

- Control of chemical release

- Safe assembly and handling

- Resistance to extreme temperatures (-50°C to 150°C)

Benefits

- Reliability

- Durability

- Safe to use

- PFAS-free